- By Admin

- 2025/8/5

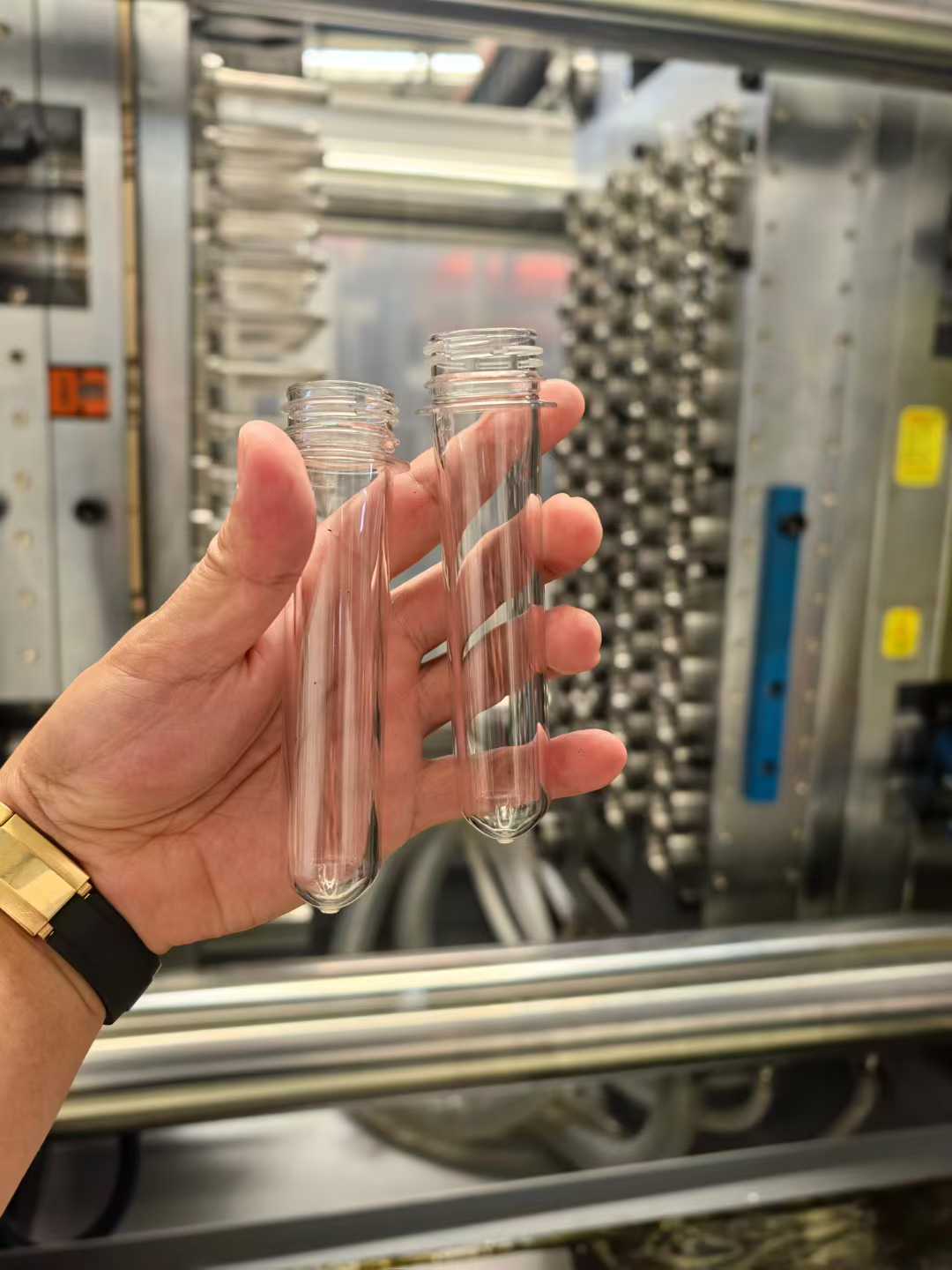

72 Cavity PET Preform Mould Design & Manufacturing: Precision Engineering for High-Volume Production

Introduction

In the competitive world of PET preform manufacturing, efficiency and precision are critical. As a leading expert in 72 Cavity PET Preform Mould Design & Manufacturing, we specialize in high-cavitation moulds that maximize productivity while maintaining superior quality. This article explores the key aspects of PET preform mould design, manufacturing processes, and the benefits of high-cavity moulds for large-scale production.

Why Choose a 72-Cavity PET Preform Mould?

A 72-cavity PET preform mould is ideal for manufacturers looking to optimize output while reducing cycle times and operational costs. Key advantages include:

High Production Efficiency – More cavities mean higher output per cycle, making it perfect for large-scale PET bottle preform production.

Cost-Effective Manufacturing – Reduced per-unit cost due to economies of scale.

Consistent Quality – Precision engineering ensures uniform wall thickness, weight, and dimensions across all cavities.

Energy & Resource Savings – Higher cavitation reduces energy consumption per preform.

Key Considerations in 72 Cavity PET Preform Mould Design

Designing a high-performance 72-cavity PET preform mould requires expertise in:

1. Hot Runner System Optimization

A well-designed hot runner system ensures uniform melt distribution, minimizing material waste and cycle time.

Advanced nozzle and gate technology prevents drooling and stringing.

2. Cooling Channel Design

Efficient cooling is critical for maintaining fast cycle times.

Conformal cooling channels improve heat dissipation, reducing warpage and improving preform quality.

3. Cavity & Core Precision

High-grade steel (e.g., H13, S136, or Stainless Steel) ensures durability and corrosion resistance.

CNC machining and EDM processes guarantee tight tolerances for consistent preform dimensions.

4. Ejection System Reliability

A robust ejection mechanism prevents sticking and ensures smooth demolding.

Balanced ejection force avoids deformation in high-cavity moulds.

Manufacturing Process for 72 Cavity PET Preform Moulds

Our PET preform mould manufacturing process includes:

CAD/CAM Design – Advanced software for 3D modeling and simulation.

Precision Machining – CNC milling, grinding, and EDM for high accuracy.

Quality Inspection – CMM (Coordinate Measuring Machine) verification for dimensional accuracy.

Testing & Validation – Trial runs to ensure optimal performance before mass production.

Applications of 72 Cavity PET Preform Moulds

These high-cavity moulds are widely used in:

Carbonated Soft Drink (CSD) Bottles

Mineral Water Bottles

Edible Oil & Juice Containers

Pharmaceutical & Cosmetic Packaging

Conclusion

Investing in a high-quality 72 Cavity PET Preform Mould enhances production efficiency, reduces costs, and ensures consistent product quality. As a trusted PET preform mould manufacturer, we deliver precision-engineered solutions tailored for high-volume production needs.